Orbital Welding of Stainless Steel Tubing for

Biopharmaceutical,

Food and Dairy Applications

by

Barbara Henon, Ph.D., Arc Machines, Inc

Orbital welding has been proven to be a very effective method for joining of stainless steel tubing for systems in which the products flowing through them must be maintained in a clean and/or sterile condition. The capability of making smooth, crevice-free welds that maintain uniformity and consistency for thousands of joints have made orbital welding technology the accepted joining technology for the semiconductor and biopharmaceutical industries in the United States. Crevice-free welds are essential for controlling the growth of microorganisms in hygienic piping systems.

The food and dairy industries in the United States, which have been slow to adopt orbital welding, have shown an increasing awareness during the past year or so that the joining technology used for the fabrication of sanitary piping systems is fundamental to achieving and maintaining cleanability and sterilizability and are taking steps to improve the hygienic condition of their piping systems.

The food and dairy industry is following the lead of the bioprocess industry which introduced a new standard for the design and fabrication of bioprocessing equipment, including piping, (ASME Bioprocessing Equipment Standard BPE ‘97) in November, 1997. The 3-A Sanitary Standards Committee in collaboration with the American Welding Society (AWS), has just published the AWS D18.1 Standard for welds in stainless steel piping systems which come in contact with the product.

This standard is more precise and well defined than previous standards used by the food and dairy industry. However, breweries, both in the USA and abroad, have long recognized the advantages of orbital welding for achieving a high level of cleanliness in their piping systems. The demand for higher standards is driven by new technologies including bioprocessing and advanced food processing technologies, as well as by the global marketplace. International trade in biopharmaceutical as well as food and dairy products has led to improvements in plant construction methods abroad, including the introduction of orbital welding, to meet the more exacting requirements for export, particularly to the USA.

The standards writing groups have had to deal with defining weld acceptance criteria and related issues including metallurgical considerations, such as the optimal sulphur content of 316L stainless steel, and the amount of permissible discoloration of the weld and heat-affected zone. These issues will be examined as well as orbital welding standard operating procedures (SOPs) that have been shown to result in high productivity and excellent weld quality.

|

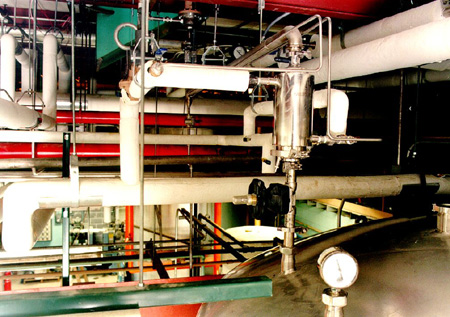

Figure 1. Water for injection (WFI) is one of the most common applications

of orbital welding in the pharmaceutical industry. Welds must be smooth

and crevice-free in order to meet WFI standards for injection into the human

body. Photo courtesy of Pfizer Animal Health.

|

|

|

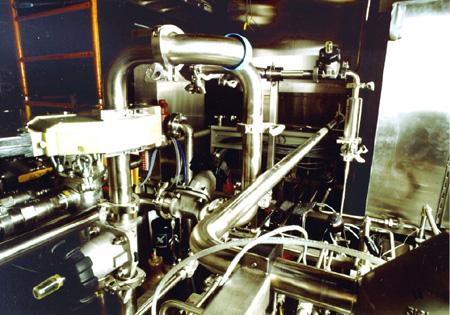

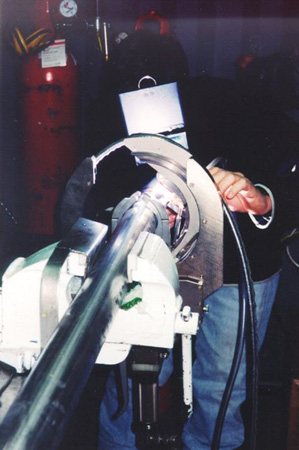

Figure 2. An Arc Machines Model 9-2500 weld head (arrow) mounted on 2

inch OD critical piping on a bioreactor skid. Photo courtesy of B.Braun

Biotech

|

|

Biopharmaceutical. Orbital welding has been used for DI (deionized) and WFI (water for injection) piping systems throughout the pharmaceutical industry since the 1970’s. For example, Figure 1 shows a WFI system at the Pfizer Animal Health facility in Missouri. Orbital welding has now been used for several pharmaceutical installations in Latin America.

One example is the Fiocruz Instituto de Technologia em Immunobiologicos in Rio de Janeiro, Brazil which used orbital welding for joining piping systems for cold water, WFI, hot DI water and compressed air at a state-of-the art R&D and production facility for the manufacture and production of vaccines. Orbital welding is frequently used for installing process equipment on-site such as the large fermenter for antigen production which was installed in a class 100,000 clean room at the Fiocruz facility. Welding standards at this facility had to meet exacting criteria required for export of the vaccines to countries outside of Brazil. Orbital welding is used by equipment manufacturers (OEMs) such as the Paul Mueller Co. in Springfield, Missouri who use orbital welding to fabricate their multi-effect stills which are used to distill water for high-purity pharmaceutical applications.

Another common application of orbital welding is the installation of skid- mounted equipment. Biopharmaceutical equipment is frequently installed on "skids" with associated equipment and connecting piping which are fabricated off-site. This offers flexibility in locating the equipment on-site and facilitates installation, eg, orbital welding is used for joining the critical piping which delivers gases to the bioreactor on the bioreactor skids made by B.Braun Biotech in Allentown, Pennsylvania as shown in Figure 2.

Food Industry. Several of the major food industry suppliers have begun to use orbital welding. Kraft Foods has purchased orbital welding systems for several of its plants including Springfield, Missouri, Allentown, Pennsylvania, and New Ulm, Minnesota. They find it practical to have an orbital welder on-site for maintenance jobs and for small installations they can do themselves without having to hire a contractor.

Procter and Gamble has installed piping systems in several of its plants including food and chemical plants. Procter and Gamble has now specified that orbital welding be used in all new construction wherever practical. Several fabricators including APV Crepaco and Central States Industrial have been using orbital welding to manufacture equipment and fittings for food and dairy applications for at least 10 years.

|

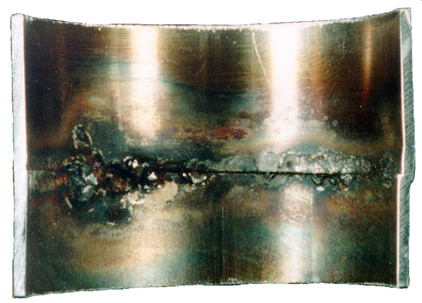

Figure 3. A manual weld taken from an operating pharmaceutical plant.

This weld has defects which include lack-of- penetration, misalignment,

a huge crevice, and discoloration due to poor ID purge. This weld would

be considered unacceptable by any sanitary standard.

|

|

|

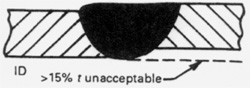

Figure 4. An orbital weld on 316L electropolished stainless steel.

The weld is fully penetrated with a uniform crevice-free inner

weld bead with good alignment. The ID was purged with argon

containing 8 ppm of oxygen which resulted in slight discoloration

of the HAZ. This weld would be acceptable for most food, dairy

and pharmaceutical applications

|

|

NAFTA (North Atlantic Free Trade Agreement) has spiked an interest in orbital welding in Mexico to meet new specifications for export to the USA and Canada. More food industry end users in Mexico are now specifying orbital welding. Jumex, (Jugos de Mexico), uses orbital welding to weld 316L electropolished tubing in sizes from 2 to 4 inches OD for pulp, fruit juice and dairy applications. In India, a country where skilled manual welders are scarce, the Dynamix Dairy successfully orbitally welded the stainless steel piping systems in a cheese plant making process cheese slices for McDonalds.

|

Figure 5. A valve manifold to control CIP and product flow in

a brewery fabricated by orbital welding.

|

|

Breweries. Breweries have recognized from the beginning the need to control microbial growth in their process piping. The Anheuser Busch Brewery in Van Nuys, California which orbitally welded about 11 miles of 4 and 6 inch schedule pipe was one of the first orbital welding applications. Orbital welding is particularly important for making cold filtered and draft beer that are not pasteurized such as Miller Genuine Draft and Rainier cold filtered beer. Most of the major breweries in the USA and several in Latin American countries including Mexico, Nicaragua, Argentina and Brazil have done successful orbital welding installations. The Kaiser Brewery in Sao Paulo recently replaced 3,000 manual welds with orbital welds.

CIP Systems. An Arc Machines Model 95-6625, an open-frame type weld head with wire feed capabilities, was recently used in Nicaragua to install product lines, CIP (clean-in-place) and related piping at "La Victoria" brewery. A complex system of valves, typically computer controlled, are used to direct either cleaning solutions, rinse water, or product through the process lines. A manifold (shown above) consisting of 10 valves for control of CIP and product flow was fabricated by orbital welding using a standard weld head. It was determined that this assembly could be made even more compact by using a narrower weld head such as Arc Machines’ Model 8-4000 so that spacers placed between the valves to allow access for the standard head could be eliminated. This would not only make the assembly more compact but would also would reduce the total number of welds in the manifold.

Weld Heads and Power Supplies

Orbital welding done with the GTAW process can be done as an autogenous (fusion) weld in which the tube ends being welded are simply melted by the arc and fused together, or filler, usually in the form of wire, can be added to the weld. An inert gas is used to protect the molten weld puddle and tungsten electrode from oxidation. Orbital welds are usually done in-place with the tube or pipe remaining stationary and the electrode or torch "orbiting" around the weld joint to complete the weld. Pharmaceutical and other hygienic welds in the United States are typically done as welds square butt weld without filler. However, in Europe and Latin America, the addition of filler may be required for some sanitary applications. For fusion welding the power supply controls weld parameters including primary and background pulsed current, pulse times, travel speed (RPM), level times, etc. Fusion welds are normally done in a single pass with the current reduced in a series of timed steps called levels. After the weld is finished or "tied-in", the current is gradually reduced in a timed downslope until the arc is extinguished. The purge is continued until the weld metal is cooled enough to prevent oxidation which is typically about 30 seconds.

If filler is to be used, the power supply must have additional controls for feeding wire into the weld, and may also have controls for torch oscillation and electronic control of the arc gap (AVC), which is the distance between the end of the electrode and the tube or pipe. This is important because the arc gap affects the arc voltage and thus the heat input into the weld and should be as consistent as possible to achieve repeatability of results.

Weld Parameters

Actual values of weld parameters vary with tube and pipe dimensions. For fusion tube welds, weld current is based on wall thickness with about 1 ampere of weld current for each 0.001 inch. RPM of the weld head rotor is based on tube diameter to arrive at a typical travel speed of 5 inches per minute. This would be 1.6 RPM for a 1.000 inch tube or 0.8 RPM for a 2 inch tube. Weld parameters are recorded on a weld schedule sheet for each size of tube or pipe and stored in the power supply memory.

Weld heads for fusion welding are typically enclosed. Enclosed weld heads are filled with inert gas during welding and provide optimal protection from oxidation for the outside of the weld. Since there may be some separation of tube ends during welding which allows the mixing of gases between the ID and OD of the tubing, enclosed heads help to maintain a better purge on the inside of the tube as well.

The size range of orbital fusion welding with enclosed weld heads is from 1/8 inch to 7 inches OD. Weld heads come in a range of sizes with each size head accommodating several tube sizes. For example, the Model 8-4000 narrow weld head can weld the sizes from 1 to 4 inches which is the range most commonly seen in biopharmaceutical applications. Tube clamp inserts of the appropriate size are installed on both sides of the weld head to hold the tubing in place for welding. The standard electrode position is in the center of the weld head, but the electrode can be positioned to accommodate fittings or components having "stick out" too short to reach the center of the head.

|

Figure 6. The manual GTAW process. The welder holds the torch

and is shown adding filler to the weld. Inert gas is used to protect

the weld metal and electrode from oxidation.

|

|

Industry standards are probably the most important determinant of weld quality. This is because installers are reluctant to spend money or time to achieve results that are not transparent to the end user. The 3-A Sanitary Standards were published in the 1950s by the dairy industry as a guideline for material selection and fabrication techniques appropriate for sanitary systems. The 3-A Accepted Practices for Permanently Installed Sanitary Product-Pipelines and Cleaning Systems was used by the food and dairy and, until just recently, by the pharmaceutical industry as a guideline for the fabrication of sanitary piping systems. 3-A selected 300 series stainless steel for equipment and piping having contact with the product and established guidelines for welding in recognition that fabrication techniques would have an impact on performance of the system.

At the time it was published, the 3-A standard applied only to manual welding. Nevertheless, some of their recommendations are still appropriate today for orbital welding. For example, they specified the Tungsten Shielded Arc Method which is the same process (gas tungsten arc welding or GTAW) that is used in most orbital welding equipment. Both manual and orbital GTA welding can be done either as a fusion process or with the addition of filler. 3-A also required that all sanitary welds be fully penetrated to the ID, and that all welds having "pits, craters, ridges, or embedded foreign materials" be removed and properly rewelded.

3-A also insisted that an inert back-up gas be used on the tube ID to protect the weld from oxidation, and that a borescope be made available to inspect the interior of the weld. Current standards are more specific regarding the level of purge required, the number of welds to be examined with a borescope, and the inspector’s qualifications. 3-A called for acceptable sample welds to be provided at the beginning of each day. For a manual weld, a test sample or test coupon demonstrates that the welder has the skill to make an acceptable weld. For orbital welding, the repeatability of the process offers some assurance that the test coupon will be representative of the quality level of subsequent welds on that material. Recent standards for sanitary welding all require preconstruction weld samples and daily test coupons.

| |

(a) Acceptable

|

|

| |

(b) Misalignment (Mismatch)

|

|

| |

(c) OD Concavity

|

|

| |

(d) ID Concavity (Suckback)

|

|

| |

(e) Lack of Penetration: None Allowed

|

|

| |

(f) Convexity

|

|

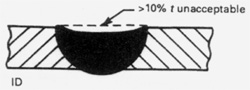

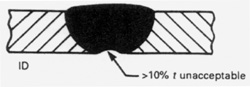

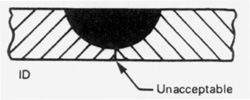

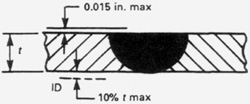

Figure 7. Weld profiles showing limits for concavity, convexity,

misalignment, etc. From ASME-BPE ‘97

Several industry groups in the USA are currently writing or have recently published standards for welding of stainless steel tubing which have direct or indirect contact with the products. Leaders in the nascent bioprocess industry recognized in 1988 that existing standards were not adequate to meet the needs of this very specialized technology which requires growing cells or microorganisms in culture without contamination by unwanted microorganisms.

In response to the need for improved standards, the bioprocess industry developed the ASME Bioprocessing Equipment Standard (BPE-97) which was released in November, 1997. The ASME BPE-97 standard offers guidelines for the hygienic design of equipment and piping systems for improved cleanability and sterilizability. The ISPE is currently writing a series of guidelines for the design and fabrication of pharmaceutical facilities and equipment. Both ASME and the ISPE Baseline Pharmaceutical Engineering Guides recognize orbital welding as the preferred joining technology for piping systems having contact with the product. Recognizing that visual weld criteria will have an important effect on maintaining the hygienic condition of the piping system, the BPE -‘97 standard includes drawings showing acceptable weld profiles and sets limits for welding defects such as concavity, convexity, misalignment, discoloration, etc.

The AWS D18.1 1998 Standard, which has just been published by the American Welding Society in cooperation with 3-A, covers welding standards for use in the manufacture and construction of dairy product processing plants. This standard will allow the owner and contractor the choice of manual, mechanized, or automatic processes, and has weld criteria and inspection protocol that are more stringent than previous standards used by the food and dairy industries for hygienic applications.

Effects of Sulphur

Since the introduction of orbital welding, two major issues affecting weld quality have persistently arisen. These are the issue of the ideal sulphur content of 316L stainless steel and the issue of the level of ID purge that should be required. Elemental sulphur is present as a contaminant and is largely removed by modern steel refining processes. AISI/ ASTM specifications for 316 and 316L stainless steel permit a maximum concentration of 0.030% sulphur since sulphur in higher concentrations promotes hot cracking of welds.

The sulphur content of stainless steel has a pronounced effect on both the surface finish of the material and on the weldability. The surface finish is affected when sulphur and manganese in the base metal combine to form manganese sulphide "stringers." These non-metallic inclusions are in the micron size range and may be removed during passivation or electropolishing leaving pits. The presence of pits makes it difficult for tubing suppliers to the high-purity industries, particularly the semiconductor industry, to meet their surface finish specifications. This has driven the semiconductor industry to specify very low levels of sulphur for tubing used in gas distribution systems.

Trace elements present in stainless steel affect weldability to a varying extent, but sulphur has by far the most dramatic effect. When the sulphur content of stainless steel is above 0.008%, the application of heat to the weld is transferred from the outside of the weld puddle towards the center carrying the heat towards the inside surface of the weldment. This provides good penetration of the weld joint and a good depth-to-width ratio. When sulphur is eliminated or reduced to very low levels the fluid dynamics of the weld puddle changes.

Importance of Purging

Purging of both the OD and ID of the weld joint with inert gas during welding is done to protect the molten weld puddle from oxidation. If oxygen is present in the gas, which is usually argon, discoloration or "heat tint" occurs on the weld and heat-affected zone (HAZ) next to the weld. Heat tint ranges in color from black and crusty, if no purge is applied, to bluish brown to pale blue or light tan or "straw color" depending on the amount of oxygen, moisture or other contaminants in the gas, on the tubing or in the base material. Discoloration is undesirable, not only because it is unattractive from a cosmetic point of view, but because its presence has been shown to have a detrimental effect on the corrosion resistance of stainless steel in direct proportion to the amount of oxygen in the purge gas.

Corrosion Resistance

Corrosion resistance. For the biopharmaceutical and food and dairy industries, the downside of discoloration caused by welding is not particulates, but the loss of corrosion resistance. It has been shown that the loss of corrosion resistance is fairly minimal for straw-coloured welds, but the loss can be reduced even further when highly purified purge gas is used.

These industries produce products that may be high in chlorides or be acidic, challenging the corrosion resistance of even 316L stainless steel. Rouging, a form of corrosion common in pharmaceutical piping systems has sometimes been traced to the HAZ of welds, although other locations, such as pump impellers and small carbon steel equipment components are more likely to show this effect.

Passivation. Passivation, which is typically done on welded piping systems to remove iron contaminants left by fabrication and to restore the passive layer on the surface of the welds and HAZ, has been shown to increase the pitting potentials and hence the corrosion resistance of both welded and unwelded tubing. However, passivation does not remove heat tint which extends well below the surface layer. Discoloration and corrosion of the HAZ was apparent on even passivated weld samples purged with only 108 ppm oxygen in the ID purge even though the pitting potential indicated a high level of corrosion resistance. Since stainless steel is not inexpensive, and since the cost of replacing it is high, it would seem advisable to use the best purge possible for any application where the service environment is aggressive.

AWS D18.2. To help owners, installers, and quality control personnel in specifying the permissible levels of weld discoloration for specific sanitary food and dairy applications, the AWS, in cooperation with 3-A, has produced the D18.2 standard which includes a color photo of a series of orbital welds purged with varying amounts of oxygen added to the argon ID purge. The ASME BPE-’97 standards group intends to reference D18.2 in their next revision. This standard should go a long way towards helping specifiers select realistic purge levels for their applications.

|

Figure 8. Orbital welding of assemblies which are part of the filtration loop

between tanks and pasteurization at the "Quilmes" brewery in Buenos

Aires, Argentina. By standardizing their fabrication procedures (SOPs)

they were able to weld at 3 times the rate for the same application done

with manual TIG welding. They were all sanitary quality welds with

100% visual inspection of the ID and zero rejects!

|

|

Effect of Welding SOPs on weld quality and productivity

SOPs. Kinetic Systems, Inc., a high-purity mechanical contractor in the USA, presented data at a local ISPE meeting summarizing results from 100,000 orbital welds in biopharmaceutical facilities during the period from 1991 to 1994. During this time they were able to reduce the reject rate of their orbital welds from a very respectable 1.8% to a remarkable 0.2%.

The company attributed this improvement in weld quality to increasing proficiency in executing their standard operating procedures (SOPs). SOPs are written procedures for fabrication and welding which include materials handling, cleaning, end-preparation of tubing, pre-tacking of weld components, purging, use of test coupons, standardization of electrode type and geometry, and many other small details that have a bearing on weld quality.

Soldaduras-Mendoza, a mechanical contractor in Buenos Aires, did a recent orbital welding installation at the "Quilmes" brewery at which they were able to establish SOPs resulting in a high level of both productivity and quality. They had to weld a large number of assemblies that comprise part of the filtration loop between the tanks and pasteurization. One end of the assembly required a weld of an elbow to a 4 inch OD tube, while the other end of the tube was welded to an elbow which was joined to a reducer welded to a 2-1/2 inch tube for a total of 4 welds per assembly.

An Arc Machines Model 95-6625 weld head was used to weld the assemblies. This head has wire feed capabilities and features a clamping device that clamps directly on to the weld joint without the need for changing tube clamp inserts. Thus the change from 4 inches to 2-1/2 inches could be accomplished nearly instantaneously with only a small adjustment of the tungsten and a change of weld programs accomplished by calling up the weld program number from the memory of the Model 227 Power Supply.

Pipefitters on the night shift were responsible for cleaning, tacking, and making the purge connections. The pre-tacked assemblies were placed on racks in groups of 5 which they called cassettes. During the day, the welding operator did the welds in a predetermined order. As each set was completed, a new cassette was presented while the welder cleaned the tungsten in preparation for welding the next set and then continued with production.

Orbital welding done in this way was found to be 3 times as productive as manual TIG welding for the same application with an average production rate of 58-62 welds per day with one welding operator and one welding system. All of these were sanitary quality welds. Since the welds were on the ends of the tubes it was possible to inspect 100% of the welds on the ID. There were zero rejects!

Conclusions

There is evidence of an increased interest in improving standards in the food, dairy, and beverage as well as the pharmaceutical industry, not only in the United States, but in Latin America and other countries as well. This is demonstrated by an increase in the use of 316L EP tubing, the demand for better purge gas quality, the use of higher purity valves, and greater interest in the FDA (Food and Drug Administration) and cGMPs (current Good Manufacturing Practices). All of these industries are under pressure for improved product safety, at a lower cost and at higher quality standards than ever before.

When end-users examine the cost-benefit ratios of new technologies, they find that orbital welding offers higher quality welds with better corrosion resistance, and in many applications higher productivity, at a reasonable cost. As these industries continue to improve their fabrication practices, the use of orbital welding technology will be at the forefront.

Acknowledgement: The author acknowledges the contribution of Angel Brond, Director of Latin American Sales for Arc Machines, Inc., whose technical support and kind assistance made this presentation at the Octavo Congreso Argentino de Farmacia Y Bioquímica Industrial, Buenos Aires, Argentina, June 1999, possible.

Reprinted from Tube International, September, 1999 from a presentation at OCTAVO CONGRESO ARGENTINO DE FARMACIA Y BIOQUÍMICA INDUSTRIAL, Buenos Aires, Argentina, June 1999

Further information can be obtained from:

Arc Machines, Inc

- Addr: 10500 Orbital Way

Pacoirna, CA 91331,

CA,

USA

- Tel: 1-818-896-9556

- Fax: 1-818-890-3724

- WWW: http://www.arcmachines.com/

- Email:

- Contact: Sue Gilbert

|