|

Performance Improvement of Rotary

Ultrasonic Testers

J Venczel, Magnetic Analysis Corp., USA

Abstract |

In Rotary Ultrasonic Testers the transducers rotate around the tube. The signal

connection to and from the transducers represents a critical part of the tester.

The task can be accomplished by one of three methods: slip rings, rotary

capacitors and rotary transformers. Naturally, each has advantages and

disadvantages. The paper analyzes these methods and offers an optimal solution.

Detailed description of a working Rotary Tester is given with test results in

tube and bar testing

Introduction

In order to insure a flawless product in the tube industry the final phase of

production must be the nondestructive inspection. Eddy current inspection is

capable of detecting surface flaws on the outside surface of the tubes but not

on the inside surface or deep in the wall of the tube. Ultrasonic inspection can

find flaws both on outside and inside surfaces, usually referred to as OD and

ID, as well as internal flaws. Utilizing the circular symmetry of tubes, it is

possible to achive100% inspection by rotating the tube in front of the

transducer or rotating the transducer around the tube. Rotating a tube at 3000

to 4000 RPM is difficult to achieve, therefore rotating the transducer allows a

higher inspection speed. Transducer rotation makes it more difficult to connect

electrical signals to and from the transducer. There are three main methods for

coupling electrical signals to rotating parts: slip rings, rotary capacitors,

and rotary transformers. The main problem with slip rings is the electrical

noise they generate; also, at high speed, it is difficult to maintain reliable

electrical conductivity between the slip ring and the brush. Rotary capacitors

are better with respect to noise but more difficult to make. Ultrasonic signals

in case of nondestructive testing are in the frequency band of 0.5 MHz to about

20 MHz, or higher. To pass such a wideband signal, the coupling capacitors have

to be in the range of 500 to 2000 pF for each channel. To realize this kind of

capacitance the capacitor plates have to be placed close to each other and have

a large surface. This, in turn, requires careful design and precision machining

operation. The parasitic capacitance between plate and ground leads to loss of

signal, while the mutual capacitance between plates of adjacent channels results

in crosstalk between channels. Rotary transformers made of high frequency

ferrite material are capable of handling the required high frequency signals but

have problems transmitting the high voltage initial pulse, which may be 500 to

600 volt. Until recently, rotary capacitors were used predominantly in rotary

testers. The application of rotary transformers is new but it has several

advantages which will be discussed in the following.

Rotary capacitors vs. rotary transformers

A rotary tester requires several channels for a typical application. Four

channels are required for a clockwise, counterclockwise, forward, and reverse

shear wave testing and a fifth channel for wall thickness measurement. Higher

inspection speed requirement leads to more channels. Testers often have seven or

twelve channels for increased inspection speed. Failure of rotary testers is

often caused by dirt or water in the rotary capacitors. Crosstalk between

channels is a serious problem and it gets worse with increased number of

channels. The coupling loss through capacitors is typically 7 to 10 dB and the

signal path includes the ground connection between the rotor and the stator.

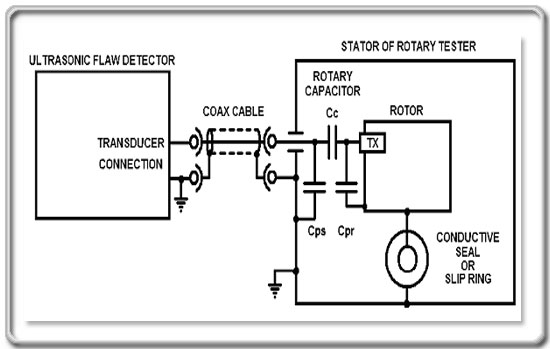

Figure 1 shows the electrical connection between a pulser receiver and a rotary

tester when using a rotary capacitor. The rotary capacitor has parasitic

components on input to stator ground and on the output to rotor ground. These

capacitances have a shunting effect, which decreases signal strength both in

connecting the initial pulse to the transducer on the rotor and connecting the

received echo signals to the pulser-receiver. The return path of electrical

connection is accomplished through the ground connection between the stator and

rotor. A conductive seal or a slip ring is used to make the electrical

connection between the bodies of stator and rotor but it also acts as a noise

source added to the input signal of the pulser-receiver. The application of a

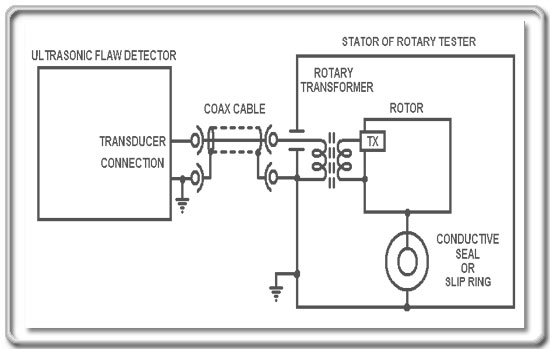

rotary transformer is shown on Figure 2. The coupling ratio is usually

one-to-one but other ratios are also possible for better impedance matching. The

effect of

| |

Figure 1.

|

|

parasitic capacitances is minimal and so is the crosstalk

between channels. The use of a conductive seal or slip ring type of ground

connection is still required but it is no longer part of the signal return. The

main problem, however, is that the ferrite transformers can not efficiently

transmit the high voltage initial pulse. To overcome this problem a remote pulse

preamplifier Was used. This, in turn, created a new problem by requiring

electrical power Conducted to the rotor. This was accomplished by adding a power

transformer to the set of signal transformers and a power supply board with

rectifier and DC-to-DC converters. The end result was an ultrasonic rotary

tester with rotor mounted electronic processing circuits.

| |

Figure 2.

|

|

Rotary ultrasonic tester with on-board electronics

The example for this product is a seven-channel rotary tester. Three of the

channels are set up to operate in compression mode for longitudinal wave testing

and four to operate in shear wave mode. The pulser of the ultrasonic flaw

detector is set up to operate with a reduced amplitude initial pulse, since it

functions only as a synchronizing signal for the pulser circuit on the rotor.

Each channel of the flaw detector is connected to the rotary by a single cable.

This cable has to conduct signals in both directions. The approximately 10V

amplitude initial pulse is generated in the flaw detector and connects to the

rotor- mounted pulser via the

rotary transformer. The 500V amplitude output of the pulser is connected to the

transducer. The echo signals received by the transducer are connected to the

input of the preamplifier in the pulse-echo arrangement. You can set the gain of

the preamplifier in four steps by slide switches on the PC board individually

for each channel. For best signal-to-noise ratio the gain of the preamplifier

has to be as high as possible without saturation. On the other hand, in some

applications the signals are very strong and the amplifier gain has to be

reduced to prevent saturation.

The slide switches allow a coarse setting of the gain in 6 dB steps. The output

impedance of the preamplifier is 50 ohm to match the characteristic impedance of

the interconnecting

| |

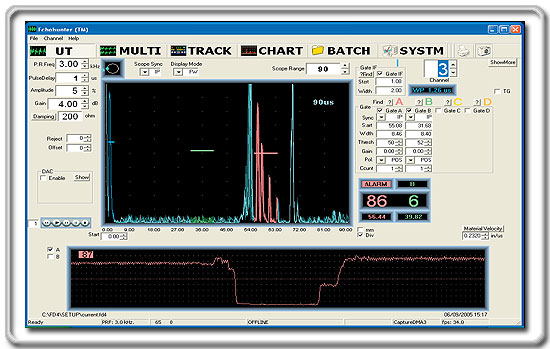

Figure 3.

|

|

cable. To be able to use a single cable to conduct signals in

both directions, we use a technique that is called “amplitude division

multiplexing”. The amplitude range of +/-5 volts is assigned to the preamplified

echo signals from the rotor to the flaw detector. The -5 to -10 volts range is

assigned to the transmission of synchronizing initial pulse from the flaw

detector to the pulser on the rotor. In evaluations the signal to noise ratio

was found to be about 10dB better compared to the traditional rotary tester.

Figure 3 shows the setup screen of the ultrasonic tester detecting a 0.3 mm deep

and 0.3 mm wide surface notch. The bottom of the screen shows the strip chart

recording of a calibration standard with signal amplitudes on and off the notch.

On the A-scan presentation, the signal amplitude is 86% under the red gate while

the noise level is 6% under the green gate. Ground loop noise is practically

eliminated because of transformer coupling. It is hard to measure numerical

improvement in resistance to electromagnetic interference, EMI, but it appeared

to be less. Crosstalk between channels is so low that it is not a problem any

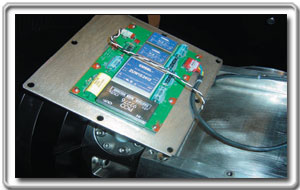

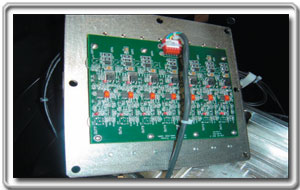

longer. The most difficult problem we faced during the design was to mount the

circuit boards in such a way that they can withstand the centrifugal forces

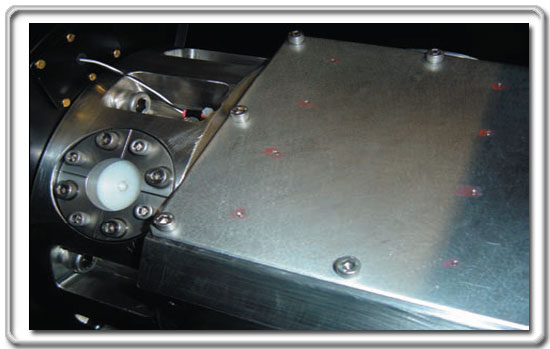

during operation. Figures 4, 5, 6 and 7 show the mounting arrangement of the

rotor-mounted printed circuit boards.

| |

Figure 4

|

|

|

| |

Figure 5 |

|

| |

Figure 6 |

|

| |

Figure 7 |

|

Conclusions

In the last few years, the rotary testers are facing a serious competition from

phased array systems. Phased arrays offer many advantages. First of all there

are no moving parts, the scanning is done electronically. Phased array systems

also offer a number of advanced features, like variable focal length, electronic

switching between compression and shear wave modes and possibly others, but many

applications do not require those. The major disadvantage of a phased array

system is the cost, which is much higher then that of a rotary tester. In multi

channel applications the rotary testers offer a lower cost alternative to phased

arrays and the addition of on board electronics improves the ability to find

small defects reliably at high inspection speed. Plans for new developments

include the addition of remote control for the rotary mounted pulser-preamplifier.

Remote control of pulse amplitude, amplifier gain and damping can add

flexibility to setup and operation. RF data links of 900 MHz or other frequency

are quite suitable for application in rotary testers.

Contact Person:

John Venczel

Engineering Manager

Ultrasonic Development

Magnetic Analysis Corporation

Phone: (914)699-9450

Fax: (914)699-9837

Email:

|